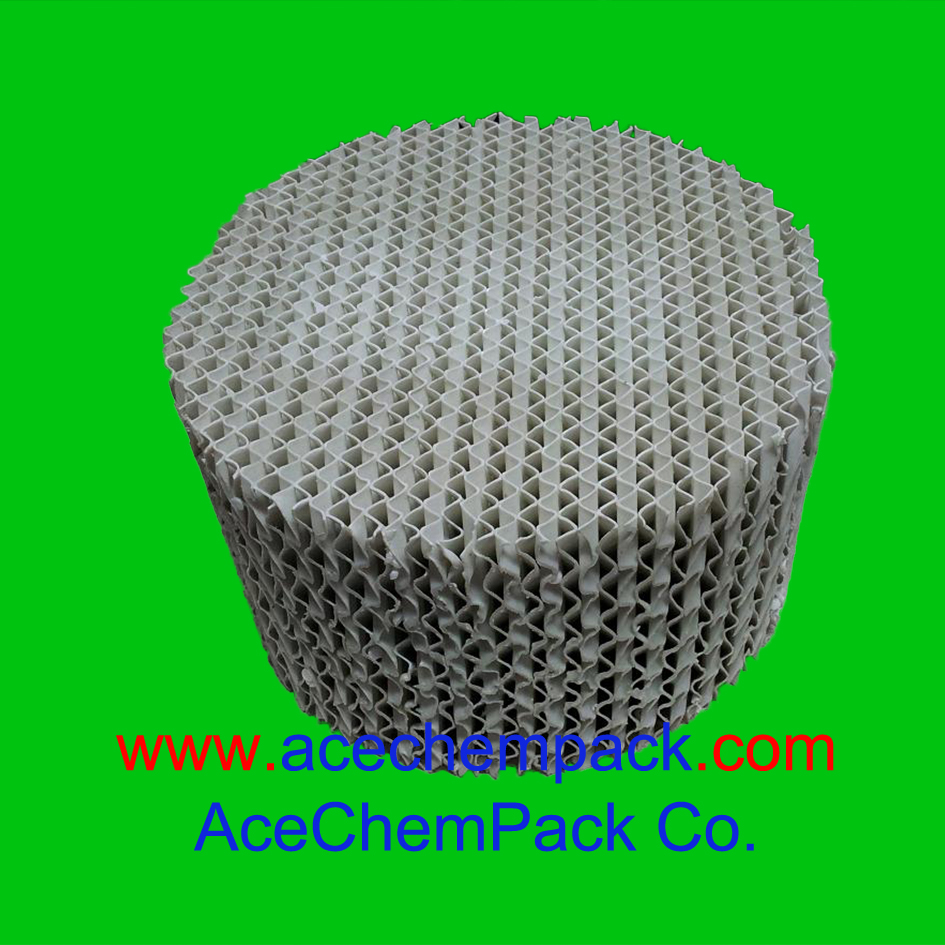

AceChemPack Ceramic Structured Packing

(Ceramic corrugated structured packing)

Introduction of AceChemPack Ceramic Structured Packing Products:

Introduction of AceChemPack Ceramic Structured Packing Products:

AceChemPack Ceramic Structured packing is also called Ceramic corrugated structured column packing. It’s formed from corrugated sheets of ceramic. Ceramic surface can generate extremely thin film liquid flow and tortuous vapor flow passages promote mixing of liquid and vapor and, at the same time, general little pressure drop. These are reasons for AceChemPack Ceramic Structured Packing has the same mass transfer efficiency as metal packing. Meanwhile, AceChemPack Ceramic Structured Packing is much more resistant to corrosion and high temperature than metal packing. The surface structure of ceramic packing could promote wetting and keep liquid hold-up to a minimum.

Advantage of AceChemPack Ceramic Structured Packing:

· The most economical range is F-factor1.5-2

· Improve capacity by up to 50% over standard ceramic saddle Column packing

· Excellent Resistance to Plugging

· Improve efficiency up to 25% over standard ceramic saddle Column packing

· Greater Heat Recovery in RTO Applications than any Random Packing

· The corrugated sheets of ceramic are vertically oriented in the packed Column, eliminating any horizontal surfaces which create resistance to fluid flow

· Pressure drop of each theoretical sheet is 0.3-1mbar Lower pressure drop by 60% or more over standard ceramic saddle Column packing

· Column Packing geometric construction greatly reduces the channeling of both the liquid and vapor and provides for more effective contact of sulfuric acid and SO3 gas.

Application of AceChemPack Ceramic Structured Packing:

· Fining process of corrosive mixtures, which have strict requirements for pressure drop and number of theoretical sheets

· Vacuum treatment under absolute pressure higher than1m bar

· Fining and distillation of halogen organic compounds. Rectifying organic halide

· Rectifying and absorbing some corrosive mixtures, which are definitely regulated in pressure drop and theoretic plate number

· Applied in some towers that contain a large quantity of natural media used to absorb nitric acid and concentrated sulfuric acid, as well as for purifying the air in chemical plants

· Operating in vacuum conditions at a bottom absolute pressure of 100pa

· Used in heat exchanger and demisting, or as a catalyst carrier

Properties:

技术参数 | 填料类型 type of the packing | |||||||||||||

700x | 470x | 450x | 450y | 400x | 400y | 350y | 250x | 250y | 160x | 160y | 125x | 125y | 100x | |

比表面积(m2/m3) | 700 | 470 | 450 | 450 | 400 | 400 | 350 | 250 | 250 | 160 | 160 | 125 | 125 | 100 |

空隙率 E% | 76 | 75 | 72 | 72 | 75 | 75 | 78 | 80 | 80 | 85 | 85 | 86 | 88 | 90 |

倾斜角(o) | 30 | 30 | 30 | 45 | 30 | 45 | 45 | 30 | 45 | 30 | 45 | 30 | 45 | 30 |

水力直径(mm) | 5 | 7 | 7 | 7 | 8 | 8 | 10 | 12 | 12 | 15 | 15 | 28 | 28 | 30 |

液体负荷(m3/m3) | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 | 0.2-100 |

最大F因子 | 2.0 | 1.8 | 2.0 | 1.8 | 2.2 | 2.0 | 2.6 | 2.8 | 2.6 | 3.0 | 2.8 | 3.2 | 3.0 | 3.5 |

压力降 mba y/m | 4.8 | 4.5 | 4.4 | 4.5 | 3 | 3.5 | 2.5 | 2 | 2.2 | 1.8 | 2 | 1.5 | 1.5 | 1.2 |

理论板数(l/m) | 7 | 5 | 3-4 | 4 | 2.8 | 2.8-3.2 | 2.5-3 | 2.3-2.7 | 2.5-2.8 | 1.8-2 | 1.9-2.2 | 1.5 | 1.7 | 1 |

堆放密度(kg/m3) | 550 | 520 | 500 | 500 | 480 | 480 | 450 | 400 | 420 | 350 | 370 | 300 | 320 | 280 |

Metal Structured Packing | Plastic Structured Packing | Metal Pall Ring | Plastic pall ring | Plastic Teller Ring | Ceramic intalox saddle ring | Molecular sieve