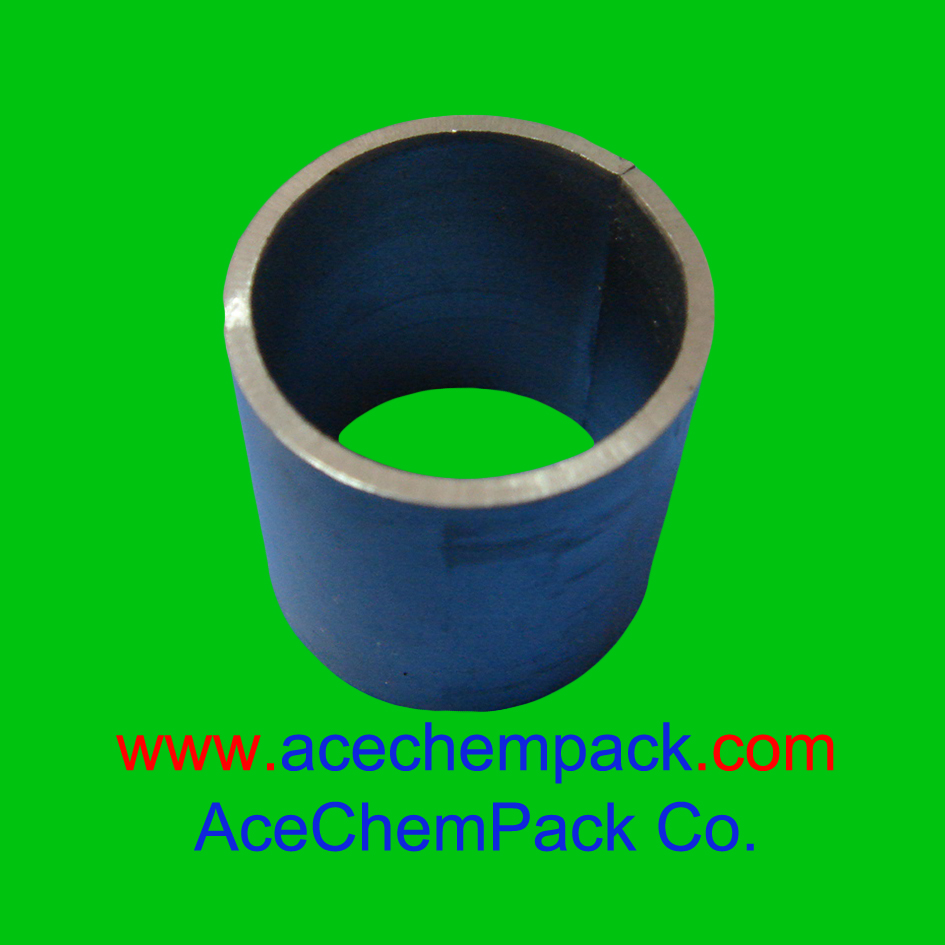

Metal Raschig Ring

AceChemPack Metal Raschig Ring Packing is proven in a wide range of mass transfer applications. A full range of Raschig Ring sizes and materials are available to tackle a wide range of separation applications. Metal Raschig Rings have a long history of improving separation efficiency. The Raschig Ring structure provides one of the largest surface areas among tower packing options and handles heavy loading, process upsets and temperature shocks. The advantages of metal packing are high capacity, low pressure drop, high separation, cold and heat resistant, longevity..

Material: Stainless steel, carbon steel, aluminum, bronze and other alloy.

Type | Dimension D x H x δ mm | Quantity n/m³ | Specific Surface (a) m2/m3 | Free Volume (ε) m³/m³ |

2/5" | 10*10*0.3mm | 768000 | 482 | 0.93 |

5/8 " | 16*16*0.3mm | 214000 | 338 | 0.93 |

1 " | 25*25*0.5mm | 52000 | 218 | 0.94 |

1.5 " | 38*38*0.6mm | 15200 | 141 | 0.95 |

2 " | 50*50*0.8mm | 6500 | 107 | 0.96 |

3 " | 76*76*1.0mm | 1830 | 74 | 0.97 |

3.5 " | 89*89*1.2mm | 1200 | 65 | 0.98 |

* Thickness of Raschig Ring could be specified by customer.

Ceramic Raschig Ring | METAL INTALOX SADDLE RING | Ceramic Intalox saddle ring | Plastic Tellerette Ring | Plastic Pall Ring | Plastic Heilex Ring | Ceramic ball