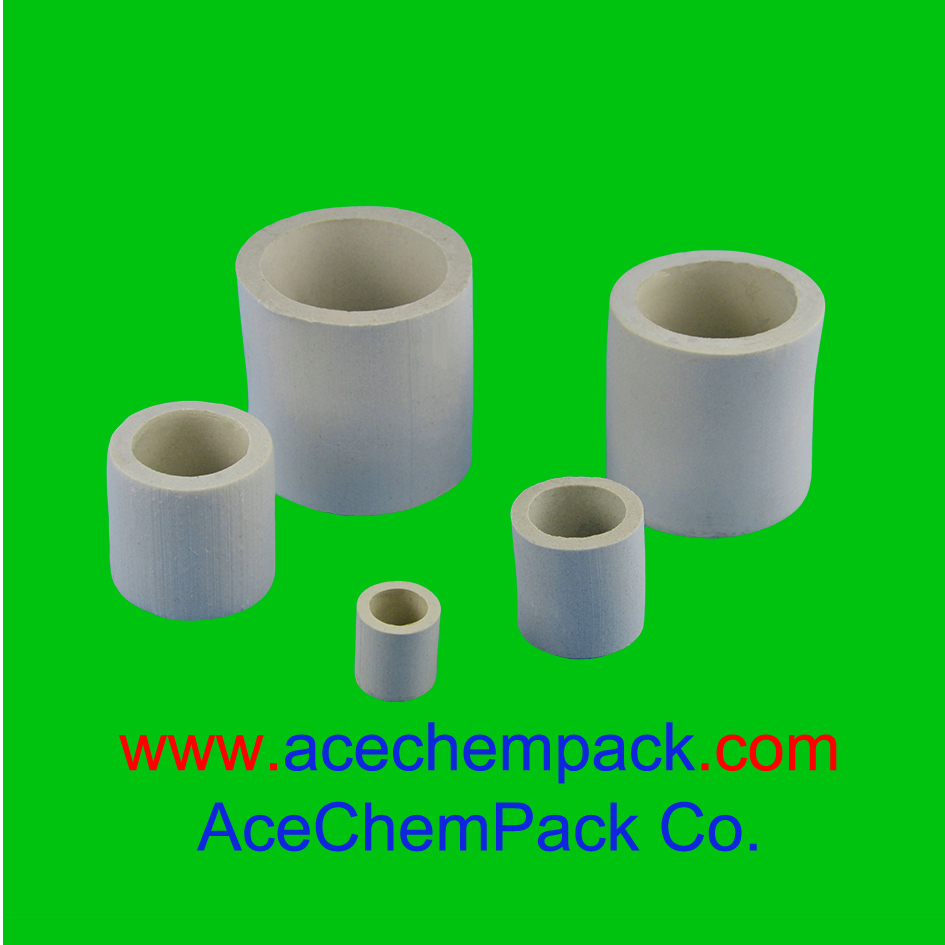

AceChemPack Ceramic Random Packing

(ceramic random column packing)

Inert Ceramic Ball |

Ceramic cascade mini ring | Ceramic Y form ring |

Introduction of AceChemPack Ceramic Random Packing Products:

Ceramic Random Packing is also named as ceramic random packing, ceramic column packing, ceramic random packings, ceramic random dump packing, packed tower packings, in shape of saddles and rings.

Ceramic surface of ceramic random packing can generate extremely thin film, which can promote mixing of liquid and vapor and generate little pressure drop at the same time. The surface of ceramic packing could promote wetting and keep liquid hold-up to a minimum. So chance for the system to be overheated, polymerixe and coke could be minimized.

We can offer ceramic random packing with a glazed construction to enhance capacity and reduce porosity. These column ceramic packing typically find their application in processes requiring high temperature and chemical corrosion resistance.

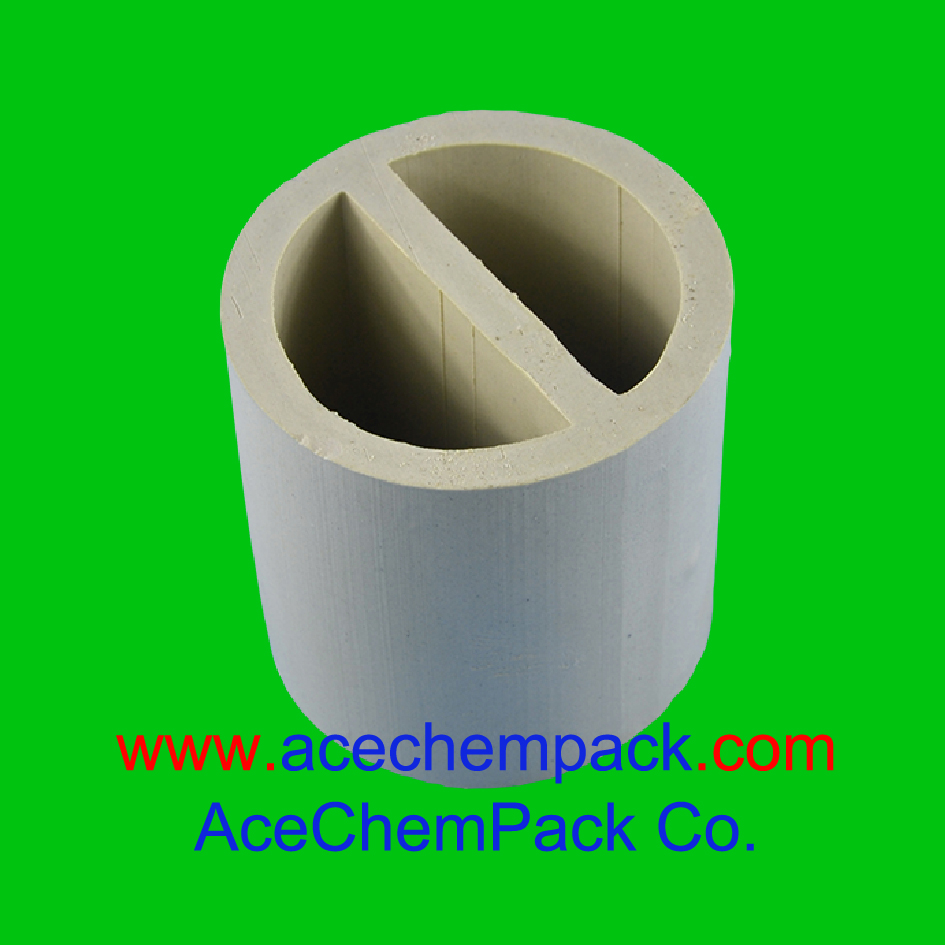

Ceramic Random tower packing list(column packing):

Ceramic Intalox Saddle Ring, Ceramic Super Intalox Saddle Ring, Ceramic Cascade Ring, Ceramic Pall Ring, Ceramic Cross-partition Ring, Ceramic Y Form Ring, Ceramic Conjugate Ring, Ceramic Raschig Ring, Ceramic Oval hole Chain, Ceramic Y Chain, Catalyst Bed Support Media (inert ceramic ball) and other ceramic column packings.

Application

Ceramic Random Column Packing is highly suitable for the conditions of higher temperature and lower temperature and can be much more resistant to all kinds of organic acid, inorganic acid and solutions except for the hydrofluoric acid than metal packing. Ceramic Random Packing/Column packing is widely used in drying tower, absorbing tower and cooling tower in the fields of chemical, petrochemical etc industries.

Ceramic packing rings are widely used in refineries, chemical engineering, acid plants, gas plants, oxygen plants, steel plants and pharmaceutical plants. Ceramic packing rings are mainly used as linings of reaction vessel in washing towers, cooling towers, reclaiming towers, desulphurization towers, drying towers and absorbing towers. They also be used as lining bricks in anti-corrosion pools and channels.

Chemical Composition

Composition | Value | Composition | Value |

SiO2 | >69% | CaO | <0.25% |

Al2O3 | 15-25% | MgO | <0.2% |

SiO2+Al2O3 | >92% | K2O+Na2O | 2-4% |

Fe2O3 | <1% | Other | <1% |

Properties

Item | Unit | Value |

Specific heat | KJ/Kg | 840-900 |

Acid Resistance | % | 99.98 |

Density | Kg/m3 | 2300-2400 |

Water absorption | % | <0.2 |

Hardness | Mohr Scale | 7-8 |

Shock strength | Kgf.cm/cm2 | 1.0-1.5 |

| Metal random packing | Ceramic random packing | Plastic random packing | Structured packing | Inert Ceramic ball | Ceramic honeycomb substrate | Molecular sieve |