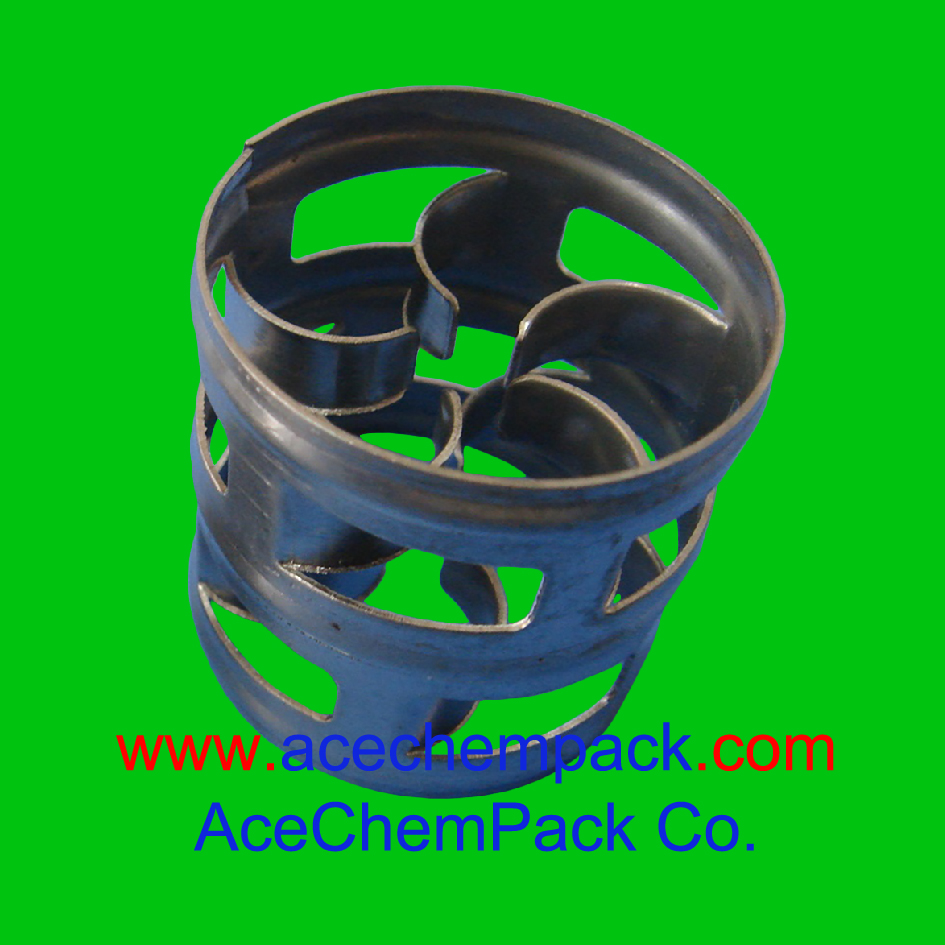

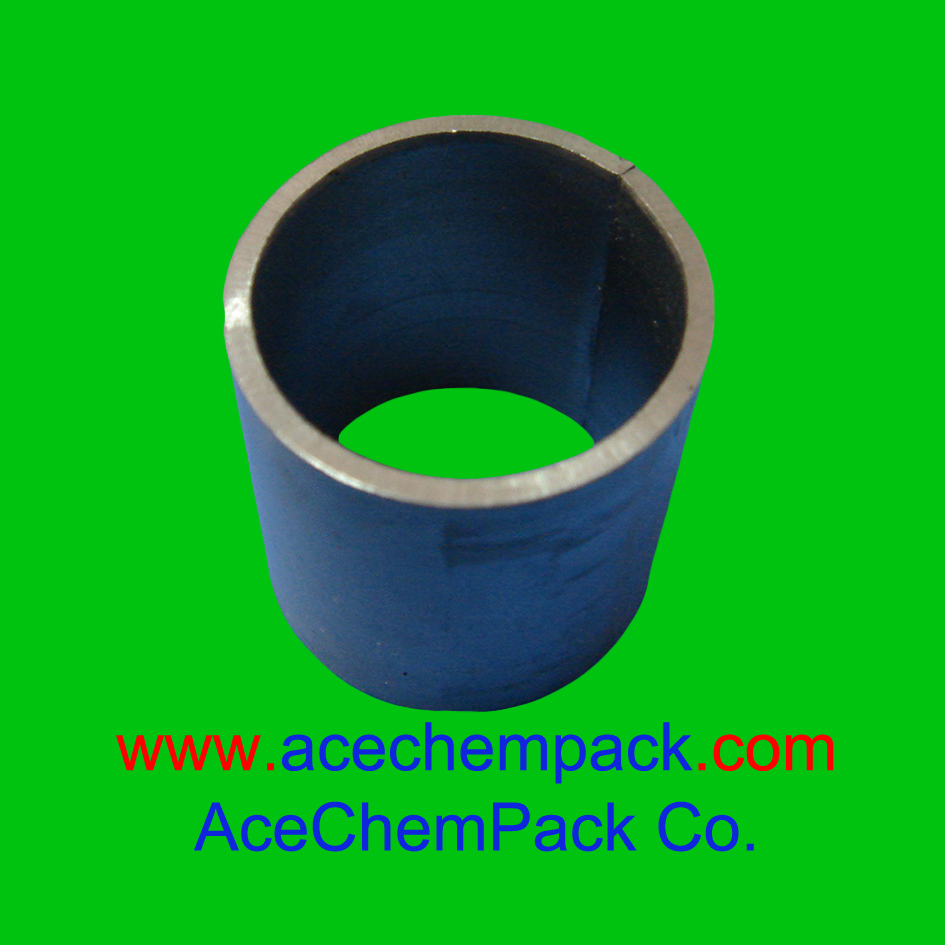

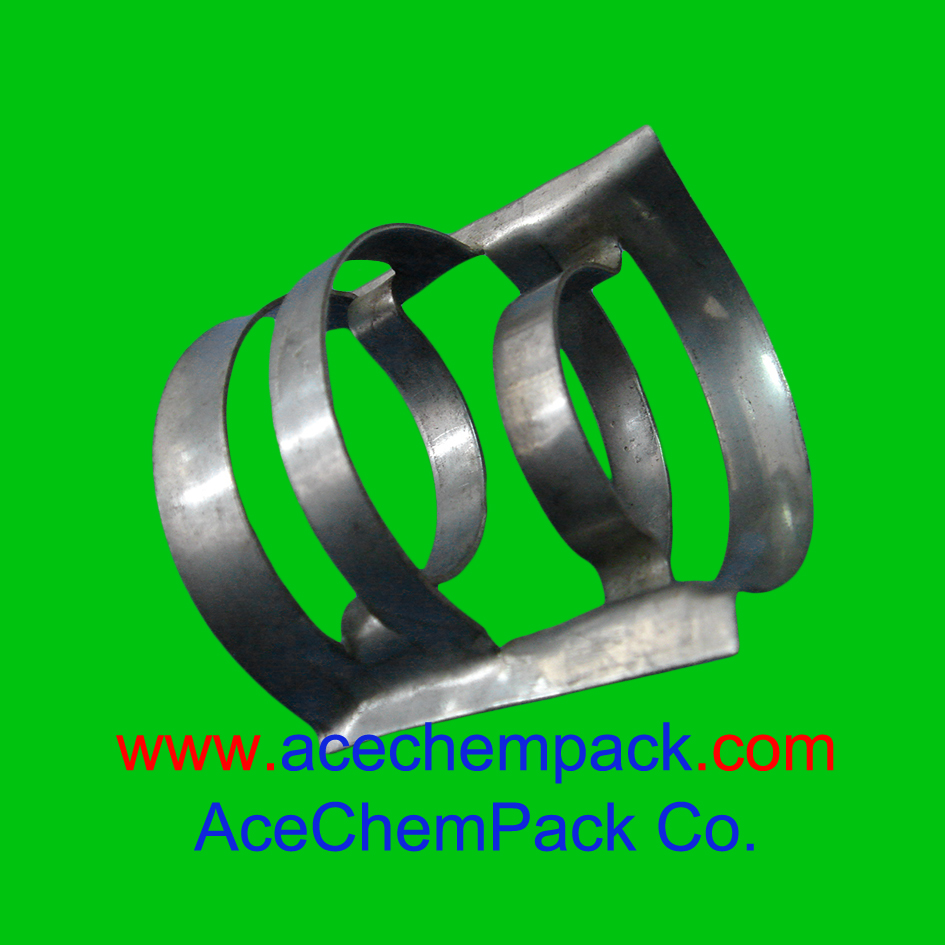

AceChemPack Metal Random Packing

(metal random column packing)

| ||

Introduction of AceChemPack Metal Random Packing Products:

High Efficiency Metal Random Packing takes the performance advantages of saddle design and ring styles, the combination structure thus creat one of the most successful high efficiency packing. Its unique shape ensures low liquid holdup and low pressure drop. The external geometry prevents the packing from interlocking or entangling, ensuring the randomness and optimum surface area within the packed bed, while the internal fingers, arches and vanes promote optimum interfacial gas/liquid contact with minimal drag or hold-up. Energy consumption is reduced, due to lower reflux ratios.

Metal random packings are available in various materials of construction such as:

Carbon Steel, Stainless Steel, Special Alloys, Titanium, Zirconium, Copper and Aluminum

The general applications:

· Various separation, absorption and desorption equipment

· Normal atmospheric pressure reduced and vacuum distillation plant

· De-carbureting and desulfuration systems

· Ethy1 benzene separation

· Iso-octane/toluene systems

| |

Metal random packing | Ceramic random packing | Plastic random packing | Structured packing | Inert Ceramic ball | Ceramic honeycomb substrate | Molecular sieve